In a previous post, we explained how serious injury and fatality (SIF) prevention increases the value of safety. In this post, we give more background on SIF and prevention steps.

In the last twenty years, the U.S. has seen a great improvement in the Total Recordable Incident Rate (TRIR). The rate dropped from about 8.5 recordable incidents per 200,000 working hours in 1993 to fewer than 3.0 incidents per 200,000 hours in 2016.

However, there’s another trend occurring at the same time: the number of life-changing injuries and fatal incidents has been on a much slower decline. In fact, it has increased in the past three years. It seems that organizations are doing really well in preventing non-fatal injuries (e.g. sprained ankles, paper cuts, minor burns) but serious injuries and fatalities (SIF) continue to occur. What can companies do to get better at SIF prevention?

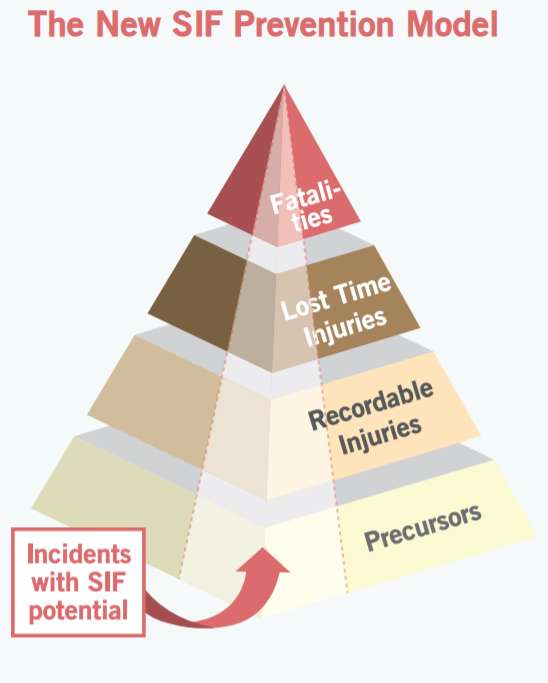

They should start by going back to basics with Heinrich’s classic safety triangle. Heinrich theorized that for every major injury or fatality, there were 29 minor injuries and 300 non-injury incidents. But when looking at this triangle with the aim of preventing SIF, safety professionals now realize there’s an idea not represented: not all non-injury incidents are equal in terms of their potential for resulting in SIF. In order to prevent SIF from occurring, we have to isolate that part of the triangle with the potential for SIF and prevent those incidents from occurring.

A white paper from the Campbell Institute, Serious Injury and Fatality (SIF) Prevention: Perspectives and Practices, proposes a revised design of the safety triangle for SIF prevention. In this new diagram, incidents with SIF potential are represented as a slice of the original safety triangle. This subset of incidents with SIF potential is different than those outside of it. They have different root causes and contextual factors, or precursors, leading up to them. Here’s the revised triangle from the Campbell Institute’s white paper:

The paper recommends three steps for developing serious injury and fatality intervention strategies:

1) Educate on SIF Exposure

Everyone in the organization should receive education on SIF exposure, especially with the new way of thinking about near misses and their relation to recordables, lost-time injuries, and fatalities. Introduce people to the new triangle for SIF prevention.

2) Focus on SIF Potential

Provide training to workers to identify and eliminate SIF potential, as this will help them to be proactive in preventing life-threatening and life-changing incidents before they can occur.

3) Identify SIF Precursors

Conducting gap analyses of procedures, controls and employee behavior helps safety professionals determine the precursors that could lead to serious injuries or fatalities if left unchecked.

Using these recommendations and the new model for SIF prevention can help organizations get to the next stage of safety. While industry as a whole should be proud of the overall reductions in non-fatal injuries, there is still work to be done to prevent and eliminate fatalities and the most serious injuries.

Treating all minor incidents and near misses as if they have the potential to result in SIF can divert attention away from incidents that have the most potential for something much more serious. Taking this targeted approach can successfully protect workers and improve safety.

View the recording of our webinar with TapRooT® to learn how you can enable a human factors-based incident investigation lifecycle, and how the integration of Enablon and TapRooT® facilitates the tasks of incident investigators: